TRANSITION FROM HAND LAY-UP TO DIRECT INFUSION

Pioneering in Composite Manufacture

SEAMLESS TRANSITION TO DIRECT INFUSION

Are you considering upgrading from hand lay-up or manual infusion to Direct Infusion but worried about the challenges?

At Composite Integration, we specialise in making this transition seamless and straightforward. Through our consultative process, we will work with you to create a solution which will reduce costs, maintain production schedules, and equip your team with essential skills for now, and in the future. Trust us to navigate you through this transformation, boosting your operational efficiency and profitability along the way.

Let our passion for excellence and commitment to customer success be your guide to the next level in boat manufacturing.

Taking the Technology Further

WHAT IS DIRECT INFUSION?

A traditional meter-mixing machine can be used to dispense mixed resin 'on demand' into a bucket. This method is widely used for custom or low-volume production however, it presents a number of challenges and limitations:

- It's Labour Intensive

- Quality can vary significantly

- It's not suited to high production volumes

- Workers are exposed to chemical vapours

- It's limited to using only certain materials

- It presents higher levels of waste

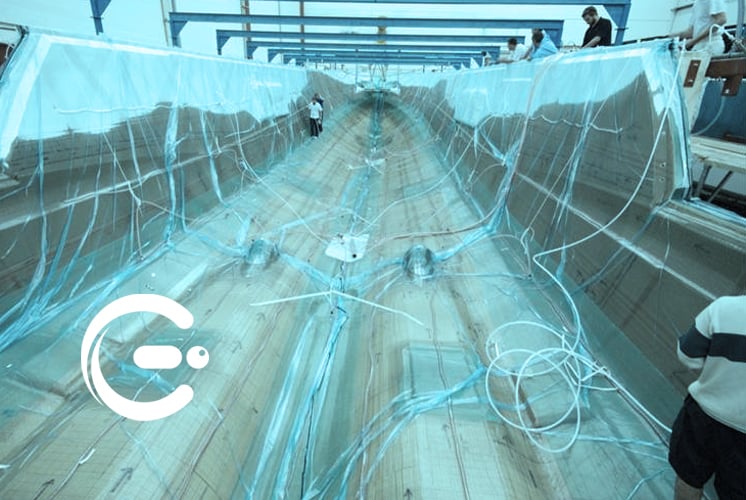

In response to these limitations, Composite Integration are proud to have pioneered the Direct Infusion Process. As the name suggests, Direct Infusion uses positive pressure to inject resin directly into the infusion process. This process is much more reliable, considerably safer, and enables you to consistently reproduce quality parts.

Our CIJECT® range of machines enable you to have complete control over the composites process. The addition of strategically positioned in-mould pressure sensors (IMPS) to monitor infusion pressure, helps control flow rate and regulate volumetric compression, enabling completely automated precision control over the entire operation. Whilst CIJECT® machines may be simple to use, they are able to manufacture the most complex parts.

WHY TRANSITION TO DIRECT INFUSION?

Transitioning from hand lay-up to Direct Infusion in boat manufacturing is not just an upgrade—it's a strategic move towards greater efficiency and superior product quality.

Here’s why making this change is essential for staying competitive and sustainable in the boat manufacturing industry:

ENHANCED QUALITY

Direct Infusion provides consistent resin-to-fibre ratio, significantly reducing the risk of voids, ensuring uniform composite structure. This leads to stronger, more reliable boats that meet high-quality standards.

ENHANCED EFFICIENCY

Streamline your production process with Direct Infusion. This method requires less manual labour, allowing you to increase output and meet customer demand more effectively.

COST SAVINGS

With Direct Infusion you can reduce consumables and waste, using materials more efficiently. Direct Infusion minimises excess resin use, helping you to cut down on costs associated with material wastage.

INCREASED SAFETY

By limiting exposure to harmful chemicals, direct infusion creates a safer work environment. This not only protects your team but also reduces health-related absences and potential liabilities.

MORE SUSTAINABLE

Direct infusion is more environmentally friendly, significantly reducing the emission of volatile organic compounds (VOCs). Align with regulations and demonstrate your commitment to sustainability.

ENHANCED AESTHETICS

Products finished with Direct Infusion often require less post-processing. This not only saves time but also enhances the final appearance of your boats, making them more appealing to consumers.

HOW WE DO IT

We care about your success, and that's why we take a fully collaborative approach to every project we undertake.

For you, we are Explorers, Engineers and Enablers.

ALWAYS A BETTER WAY

We care about your success.

Whatever your goals, whatever your ambition, we're here to make sure you have the right equipment, processes and expertise, to push the boundaries in your composite manufacturing capabilities.

- Dedicated consultancy

- Proof of Concepts & Feasibility Studies

- R&D & Prototypes

ENGINEERED FOR YOU

With 20+ years experience in the marine sector we have cultivated a climate of inspiration and innovation. CIJECT® equipment is at the heart of this.

- Simple to use, unparalleled reliability, manufactures the most complex parts.

- Gives you ultimate control over the entire composites process.

- Chosen globally, manufacturing 'Hulls for large world renowned luxury yachts.

MORE THAN A MACHINE

Others may sell you the equipment, but we go even further.

From onsite installation, to guidance throughout your project, we'll help you to produce high quality parts, more efficiently, and with less waste.

- Cloud-based Support Network

- Team Training & Education

- Ongoing Collaboration for Growth

ENABLING CUSTOMERS GLOBALLY

Sunseeker International Ltd

Adam Brangan - Director of Naval Architecture & Materials Engineering

" Composite Integration worked with us to help our team move away from conventional infusion to Direct Infusion, using CIJECT equipment. Their level of support at every stage, and the resulting efficiency improvements should be commended. "

Princess Yachts Ltd

Rob Coleman - Head of Manufacturing

" With CIJECT machines now central to our manufacturing process, we've opened new possibilities for component design, and have embraced a more creative approach with our latest product range."

CHAT TO A CI EXPERT

The journey to a more cost effective and efficient boat manufacturing process begins now.